イラストにカーソルを当ててみてね

お知らせ

すべて見る

デバイスプログラマ

1973年、国産初のデバイスプログラマを開発。国内シェアNo.1の技術力で、お客さまの幅広いニーズにお応えします。

-

豊富な実績

1973年、国内初のデバイスプログラマを開発。国内シェアNO.1の技術力で、お客さまの幅広いニーズにお応えします。

-

様々なデバイスの書き込みに対応

ユニバーサルに(マイコン、EPROM、NOR、Serial Flash、NAND、eMMC)1台のデバイスプログラマで書込み可能です。

-

大容量

NANDデバイス、eMMCなどGBクラスの大容量メモリの書込みに対応しています。

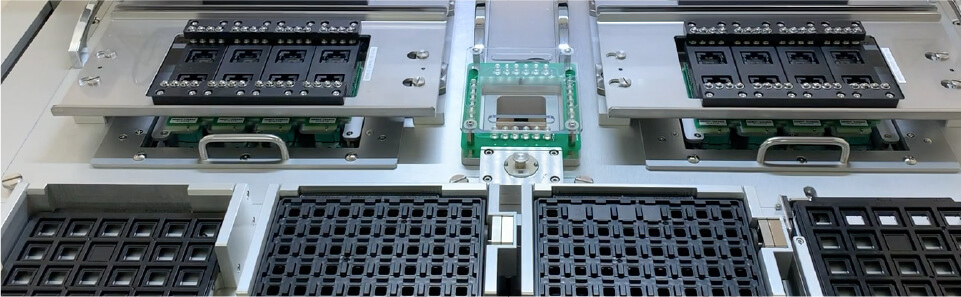

ROM書込みサービス

1998年10月にスタートしたデバイスプログラマメーカーが提供する高い技術力と確かな実績。国内No.1の設備環境を整え、高品質・低価格・短納期の生産体制を構築しています。

-

国内No.1のキャパシティ

月産3000万個の書き込みを行うことができる体制を確保。様々な書込み依頼に柔軟に対応します。

-

国内No.1の設備環境

弊社が開発したデバイスプログラマを搭載した自動機を50台設備。今後も生産性、品質の向上を計る為、自動化に向け改善を進めてまいります。

-

高い信頼性

車載メーカ様を含む大手メーカ様からの依頼をいただいております。

-

確かな技術力

デバイスプログラマを開発したエンジニアが技術サポートいたします。

タッチパネル・デジタルサイネージ

35年以上の実績と最先端の技術を誇るタッチパネルから次世代インテリアサイネージまで幅広く取り扱っております。

-

実績ある歴史

1984年に金融機関ATMや制御機器向に発売して以来、多方面で採用されています。

-

確かな技術力

タッチパネル、ディスプレイ、コンテンツを含めた総合的なご提案をしてまいります。

-

最新のデザイン

配信されるシステムだけでなく、サイネージ自体の意匠性にもこだわります。

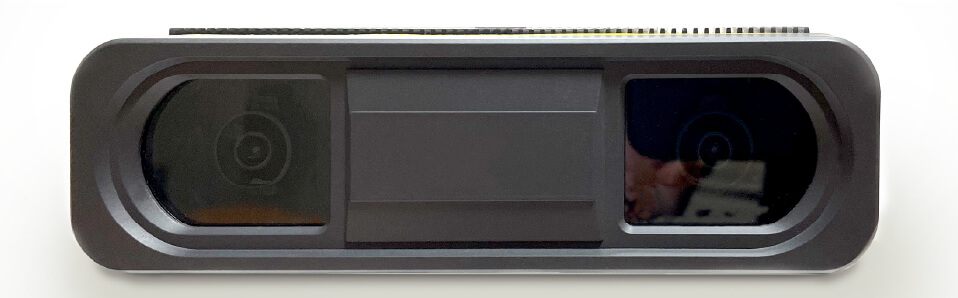

インテリジェント・ステレオカメラ

MINATOと東京工業大学発スタートアップ企業との共同開発で生まれたISC (インテリジェントステレオカメラ)。

-

検知

ドア開閉検出、車両停止位置検出、障害物検出などに採用されています。

-

検出

特定の物体を検出アルゴリズムを用いて検出します。

-

計測

任意の2つの特徴点のベクトル差を計算し計測します。

-

自動運転

SLAM(自己位置認識)を用いて実現しています。